15 Heads & 1.9 m FD61915E-A

Sublimation Textile Printer

Printhead Resolution: 3200DPI

Printing Speed: 610sqm/h

Print Width: 1900mm

Ink: Dye Sublimation Ink, Pigment Ink

Media: Transfer Paper, Poster Paper

RIP Software: Maintop, Photoprint, Neostampa, Onyx, etc.

EPSON I3200-A1 Printhead

EPSON 3200-A1 print head has 3200 nozzles, variable drop ink technology, improved printing resolution, improved color restoration degree, built-in ink column, easy to use, and supports up to four levels of gray printing.

Imported THK Mute Guide Rail

Japanese THK mute guide rail, moving steadily, longer working life, and reducing the resistance and noise of carriage moving during the highspeed printing

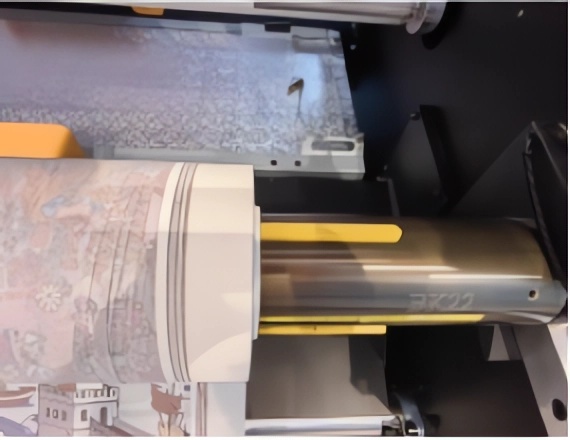

Rubber Roller

Specially designed paper transmission roller, which is for thin paper printing,20-30g paper can be printed perfectly without a wrinkle.

Smart Moisturizing Capping Station

Advanced liftable and sealed capping station, ink absorption, ink scraping is accurate.

Ink cartridge

This Fedar FD61915E-A Sublimation Printer adopts 15 liters of bulk tanks with an ink-starving alarm system to make sure of a good print job. The powerful continuous supply ink supply system provides support for the improvement of production efficiency, avoiding the frequent shortage of ink in production and the heavy work caused by back-and-forth inspection.

Capping Station

Finished integrated capping station equipped with advanced intelligent nozzle cleaning and moisturizing device, providing safe and convenient nozzle cleaning and maintenance functions, making operation and maintenance more convenient. The working principle of the automatic ink cleaning function: the digital printing machine draws the ink through the nozzle of the ink pump in the ink stack to achieve the purpose of cleaning and moisturizing, preventing the nozzle from clogging.

Pinch Rollers

This Fedar Sublimation Printer has a specially designed pinch roller made of Dupont rubber, each roller can be lifted independently to eliminate the wrinkle caused by media moving.

Feeding & Take-up System

This auto-feeding and taking-up device with a tension sensor bar makes the force even and makes the paper smoother. It's simple and convenient to take up printed media.

| Printer Model | FD61915E-A | |

|---|---|---|

| Printhead | Type | EPSON i3200-A1 |

| Nozzle Quantity | 3200 | |

| Printhead Quantity | 15 | |

| Printing Speed | 1 pass | 610 sqm/h |

| 2 pass | 300 sqm/h | |

| Ink | Color | CMYK/CMYK+2 COLORS |

| Type | Sublimation Ink, Water Based Pigment Ink | |

| Standard Configuration | Ink Level Alarm System | |

| Max Printing Width | 1900 mm | |

| Printing Media | Transfer Paper | |

| Material Transmit | Pinch roller mode | |

| Drying Method | Extra Dryer Device | |

| Moisture Mode | Full Seal Auto Moisture and Cleaning | |

| RIP Software | Maintop, Flexiprint, Neostampa | |

| Image Format | JPG, TIF, PDF, BMP, etc. | |

| Computer | System: WIN7 64bit/WIN10 64bit Hardware: Hard disk: 500G or more (SSD is recommended), GPU: ATI Mobility Memory 4G, Random Access Memory: 16G, CPU: Intel i5/i7, Gigabit LAN Transmission Interface: Dual Gigabit Ethernet Ports | |

| Work Environment | Temperature: 15°C-30°C; Humidity: 35°C-65°C | |

| Power | Input Voltage: 210-230VAC 50/60HZ 16A Machine Printing Power: 15KW Dryer Power: Max. 10.8KW | |

| Dimension | Printer Dimension: 3757*1476*1962mm Packing Dimension: 3920*1150*2110mm | |